Everything You Need to Know About Liner Sheets: Benefits, Uses, and Types

Although liner sheets may appear to be a little and insignificant component of packing.

they are essential for maintaining the quality and safety of goods while in transit and storage. We will go into great detail regarding liner sheets in this part, including their advantages, applications, and many types that are on the market.

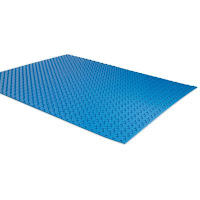

Between the merchandise and its packaging, liner sheets act as a barrier of protection. They are made to stop products from coming into contact with the outside of boxes or other containers directly. By doing this, they serve as a defense against impurities that could harm the product's quality, such as moisture, mud, dust, and others.

The fact that liner sheets improve product stability within the container is one of its main advantages. They offer an extra layer of padding that aids in dampening shocks and vibrations during transit. This is especially crucial for delicate or fragile things that need extra care and security.

Additionally, liner sheets boost a product's capacity to be stacked. They make the inside of the containers smooth, making it possible to stack things easily without causing damage or deformation. This not only increases storage capacity but also makes handling and transportation more effective.

Liner sheets are utilized in a variety of different sectors.

They are frequently used in the e-commerce and retail sectors to ship goods like electronics, glassware, ceramics, and other things that are vulnerable to harm in transit. Additionally, liner sheets are used in the food processing industry where they serve as layers of protection for perishable foods or large-scale commodities.

There are various liner sheet kinds that can be used to meet various packaging requirements. Among the most popular are kraft paper liners, which are renowned for their toughness and longevity; corrugated liners, which provide great cushioning; polyethylene liners, which resist moisture; and anti-static liners made especially for electronic components.

In conclusion, anyone involved in packaging design or logistics management has to comprehend liner sheets. They are essential for guaranteeing the safe and secure transportation of commodities because of their advantages such as protection against pollutants, greater stability, and improved stackability. Businesses may optimize their packaging solutions and protect their products along the supply chain by investigating the many types of liner sheets that are currently on the market.

.png)

.jpg)

Comments

Post a Comment