PP Sheet: The Ultimate Guide to Streamlining Your Workflow

PP Sheets: The Ultimate Guide to Streamlining Your Workflow

A PP Sheet is a

document that outlines the step-by-step process and procedures for completing a

specific task, project, or operation. It serves as a roadmap, providing clear

instructions and guidelines for team members or individuals involved in the

workflow. The sheet can be created using various formats, such as a

spreadsheet, flowchart, or a detailed written guide.

Benefits of Using a PP Sheet

1. Standardization: A PP Sheet ensures

consistency in how tasks are performed, leaving less room for errors and

variations.

2. Time Efficiency: By following a

structured process, team members can complete tasks faster and with fewer

interruptions.

3. Training and Onboarding: New team members

can quickly get up to speed by referring to the PP Sheet, reducing the time and

effort required for training.

4. Quality Control: PP Sheets help

maintain high-quality outputs as each step is well-defined and can be easily

reviewed and improved.

5. Task Delegation: When delegating

tasks, the PP Sheet serves as a clear guide, enabling effective communication

and accountability.

6. Identifying Bottlenecks: Analyzing the PP Sheet can help identify inefficiencies and bottlenecks in the workflow, leading to process improvements.

Creating an Effective PP Sheet

1. Identify the Workflow: Determine the

specific task or process that needs streamlining. Break it down into its

constituent steps.

2. Gather Information: Collaborate with

team members involved in the process to gather valuable insights and best

practices.

3. Organize the Steps: Arrange the steps

in a logical order, ensuring that each one is clear, concise, and easy to

follow.

4. Include Visual Aids: Depending on the

complexity of the process, consider using flowcharts or diagrams to illustrate

the workflow visually.

5. Assign Responsibilities: Specify roles and

responsibilities for each step to avoid confusion and promote accountability.

6. Review and Refine: Share the draft PP Sheet with relevant stakeholders for feedback. Continuously refine the document based on input.

Implementing the PP Sheet

1. Training: Conduct training

sessions to introduce the PP Sheet to all team members. Address any questions

or concerns during this phase.

2. Monitor Progress: Keep track of how

the workflow is being followed and identify any deviations. Use this data to

make necessary adjustments.

3. Continuous Improvement: Encourage team

members to provide feedback on the PP Sheet regularly. Use their input to

refine the process further.

4. Document Updates: As the workflow evolves, ensure that the PP Sheet is updated accordingly. Maintain a version control system to track changes.

Conclusion

A well-designed PP Sheet can be a powerful tool for optimizing your workflow and maximizing efficiency. By providing a standardized and clear roadmap for completing tasks, it empowers your team to work cohesively and achieve better results. Regularly review and update the PP Sheet to adapt to changing requirements and ensure that your workflow remains streamlined and efficient. Embrace the power of the PP Sheet, and you'll find yourself well-equipped to tackle any challenge that comes your way.

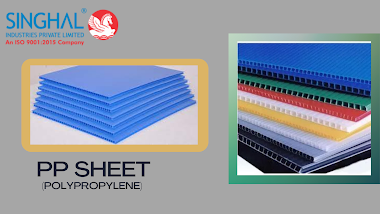

Applications: Polypropylene sheetsversatility allows it to be used in a wide range of applications, including:

Packaging: PP is commonly used in packaging materials such as bottles, containers, caps, and films due to its durability and resistance to moisture and chemicals.

Automotive: It is used in automotive parts like bumpers, interior trim, and battery cases due to its lightweight and impact resistance.

Textiles: PP fibers are used in the manufacturing of carpets, ropes, geotextiles, and upholstery due to their strength and abrasion resistance.

Medical: PP is used in medical devices and equipment like syringes, surgical instruments, and medical packaging due to its biocompatibility and sterilization resistance.

Household Items: It is used in various household products like food containers, storage bins, and furniture due to its durability and ease of molding.

Agriculture: Polypropylene is used in agricultural applications such as greenhouse covers, mulch films, and woven sacks due to its resistance to UV radiation and moisture.

Industrial Applications: PP is used in industrial settings for pipes, fittings, chemical tanks, and other components due to its chemical resistance and durability.

Stationery: PP is used to make items like folders, binders, and document sleeves due to its flexibility and ability to withstand wear and tear.

Polypropylene's widespread use is a testament to its versatility and reliability across various industries and applications. Its properties make it a popular choice for both consumer and industrial products.

Certainly! Let's delve further into some additional aspects of polypropylene:

Recyclability: Polypropylene is a highly recyclable material, contributing to sustainability efforts. It can be recycled into various products, reducing its environmental impact. Many recycling programs accept polypropylene items such as containers, bottles, and packaging.

Food Contact Approval: Polypropylene is approved for food contact applications by regulatory agencies like the U.S. Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA). This approval highlights its safety and suitability for food packaging and storage.

Thermoforming: Polypropylene's ability to undergo thermoforming processes makes it a popular choice for manufacturing various molded products. Thermoforming involves heating the material and shaping it into the desired form, enabling the production of items like disposable cups, trays, and clamshell packaging.

Injection Molding: Injection molding is another common manufacturing method for polypropylene. It involves melting the polymer and injecting it into a mold to create intricate and precise shapes, making it ideal for producing items with complex designs and details.

Fiber Reinforcement: Polypropylene can be combined with other materials, such as glass fibers, to enhance its mechanical properties and create reinforced plastics. These reinforced PP materials offer increased strength and stiffness, making them suitable for applications requiring higher performance.

Film Extrusion: PP is widely used in film extrusion processes to produce plastic films with varying thicknesses. These films find applications in packaging, agriculture (such as greenhouse covers and mulch films), and various industrial applications.

Non-toxic Nature: Polypropylene is considered non-toxic, making it suitable for applications where contact with sensitive materials or living organisms is necessary. This characteristic is particularly essential in medical and pharmaceutical applications.

Environmental Impact: While polypropylene is recyclable and offers some environmental advantages, it is still a petroleum-derived plastic. Like other plastics, improper disposal or littering of polypropylene can contribute to pollution. As such, it is essential to encourage responsible waste management and recycling practices.

Advancements in Polypropylene sheets Ongoing research and development have led to advancements in polypropylene technology. Manufacturers continue to develop high-performance grades, such as random copolymers and impact copolymers, to meet specific application requirements.

In conclusion, polypropylene's versatility, recyclability, and excellent combination of properties have made it a fundamental material in various industries. From everyday household items to critical components in medical and automotive sectors, polypropylene continues to play a crucial role in modern manufacturing and offers solutions to diverse challenges. As technology and sustainability efforts progress, polypropylene will likely remain a key material in shaping our daily lives and a sustainable future.

.png)

.jpg)

Nice Post! Thank you for sharing this informative blog, Keep post more like this. I just suggest to List Of Packaging Companies In Chennai

ReplyDelete