Unveiling the Versatility of U Panel Bulk Bags: Your Ultimate Guide

Introduction:

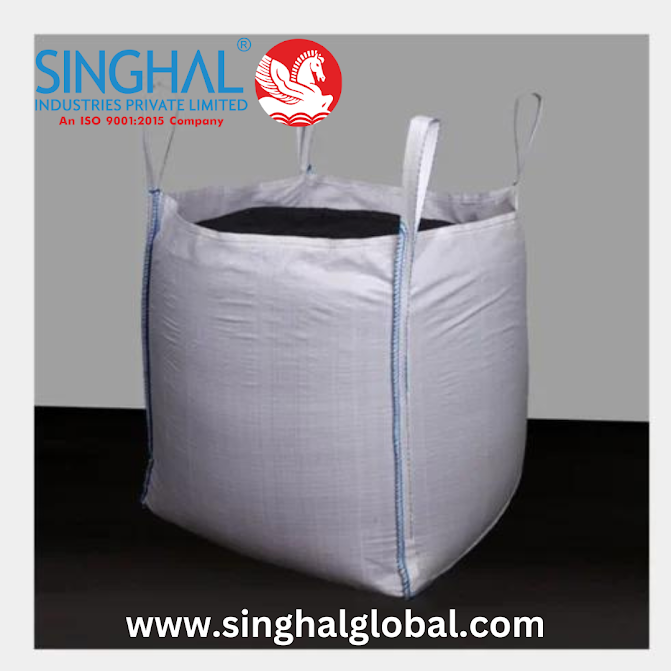

In the realm of industrial packaging, U panel FIBC bags stand out as versatile, reliable, and cost-effective solutions. These bags, popularly known for their distinctive U-shaped side panels, have revolutionized the way bulk materials are transported and stored. In this comprehensive guide, we delve into the world of U Panel FIBC Bag Exporters in Ahmedabad, exploring their manufacturing process, advantages, benefits, and much more.

Advantages of U panel bulk bags:

Structural integrity:

U panel FIBC bags are engineered with reinforced side panels, providing superior strength and stability. This design ensures that the bag maintains its shape and integrity even when filled with heavy or bulky materials.

Space optimization:

The U-shaped side panels of these bags allow for efficient stacking and storage, maximizing warehouse space and reducing transportation costs. This feature is particularly advantageous for industries dealing with limited storage space or transporting goods over long distances.

Customization options:

U panel FIBC bags can be tailored to meet specific requirements, including size, capacity, and lifting options. U Panel FIBC Bag Manufacturers in India, particularly in Ahmedabad and Gujarat, offer a wide range of customization options to suit diverse industrial needs.

Ease of handling:

Equipped with lifting loops or straps, U panel bulk bags are easy to handle and transport using forklifts, cranes, or other material handling equipment. This facilitates smooth loading and unloading operations, enhancing overall efficiency in the supply chain.

Durability:

Constructed from high-quality polypropylene fabric, U panel FIBC bags exhibit excellent durability and resistance to tearing, puncturing, and moisture. This ensures the safe and secure transportation of materials, even in harsh environmental conditions.

U panel FIBC bags are engineered with reinforced side panels, providing superior strength and stability. This design ensures that the bag maintains its shape and integrity even when filled with heavy or bulky materials.

Benefits of U panel bulk bags:

Cost savings:

By optimizing storage space, reducing material wastage, and minimizing transportation expenses, U panel FIBC bags contribute to significant cost savings for businesses across various industries.

Enhanced safety:

The robust construction of U panel bulk bags minimizes the risk of product spillage, accidents, and injuries during handling and transportation. This promotes a safer working environment and helps companies comply with regulatory standards.

Versatility:

From agricultural products and chemicals to minerals and construction materials, U panel FIBC bags can accommodate a wide range of bulk materials, making them highly versatile for diverse applications.

Environmental sustainability:

Many U panel FIBC bag manufacturers in India prioritize eco-friendly practices and materials, contributing to environmental sustainability. Reusable and recyclable options further reduce the carbon footprint associated with packaging and logistics.

Improved productivity:

By streamlining packaging, storage, and transportation processes, U panel bulk bags enhance overall productivity and operational efficiency. This allows businesses to focus their resources on core activities and achieve higher levels of output.

Conclusion:

U panel bulk bags have emerged as indispensable packaging solutions for industries worldwide, offering a winning combination of strength, versatility, and cost-effectiveness. With a growing number of manufacturers and U Panel FIBC Bag Exporters in Gujarat, and across India, businesses have access to a diverse range of U panel FIBC bags to meet their specific requirements. Whether it's transporting agricultural commodities, chemicals, or industrial materials, these bags continue to play a crucial role in facilitating smooth and efficient supply chain operations.

FAQs:

Q1. What are U panel bulk bags made of?

A1. U panel FIBC bags are typically made of woven polypropylene fabric, known for its strength, durability, and resistance to tearing and moisture.

Q2. Can U panel bulk bags be customized?

A2. Yes, U panel FIBC bags can be customized in terms of size, capacity, lifting options, and printing to meet the specific needs of different industries and applications.

Q3. Are U panel bulk bags reusable?

A3. Yes, many U panel FIBC bags are designed for multiple uses, offering a cost-effective and eco-friendly packaging solution for businesses looking to minimize waste and environmental impact.

Q4. How are U panel bulk bags transported?

A4. U panel FIBC bags can be transported using forklifts, cranes, or other material handling equipment equipped with suitable lifting mechanisms such as loops or straps.

By optimizing storage space, reducing material wastage, and minimizing transportation expenses, U panel FIBC bags contribute to significant cost savings for businesses across various industries.

Enhanced safety:

The robust construction of U panel bulk bags minimizes the risk of product spillage, accidents, and injuries during handling and transportation. This promotes a safer working environment and helps companies comply with regulatory standards.

Enhanced safety:

The robust construction of U panel bulk bags minimizes the risk of product spillage, accidents, and injuries during handling and transportation. This promotes a safer working environment and helps companies comply with regulatory standards.

FAQs:

Q1. What are U panel bulk bags made of?

A1. U panel FIBC bags are typically made of woven polypropylene fabric, known for its strength, durability, and resistance to tearing and moisture.

Q2. Can U panel bulk bags be customized?

A2. Yes, U panel FIBC bags can be customized in terms of size, capacity, lifting options, and printing to meet the specific needs of different industries and applications.

Q3. Are U panel bulk bags reusable?

A3. Yes, many U panel FIBC bags are designed for multiple uses, offering a cost-effective and eco-friendly packaging solution for businesses looking to minimize waste and environmental impact.

Q4. How are U panel bulk bags transported?

A4. U panel FIBC bags can be transported using forklifts, cranes, or other material handling equipment equipped with suitable lifting mechanisms such as loops or straps.

A1. U panel FIBC bags are typically made of woven polypropylene fabric, known for its strength, durability, and resistance to tearing and moisture.

Q2. Can U panel bulk bags be customized?

A2. Yes, U panel FIBC bags can be customized in terms of size, capacity, lifting options, and printing to meet the specific needs of different industries and applications.

Q2. Can U panel bulk bags be customized?

A2. Yes, U panel FIBC bags can be customized in terms of size, capacity, lifting options, and printing to meet the specific needs of different industries and applications.

.png)

.jpg)

Comments

Post a Comment